Surprisingly, spillage can account for a huge resource within an operation whether it is a minimal power system or heavy-industry like mining coal, in which the bigger tonnage speed may lead to enormous quantities of

Surprisingly, spillage can account for a huge resource within an operation whether it is a minimal power system or heavy-industry like mining coal, in which the bigger tonnage speed may lead to enormous quantities of material losses within a brief period. To Set or OH&S value on these inefficiencies are exorbitant but for reasons unbeknown, lots of surgeries appear to fix to allocating resources to wash the spill instead of addressing the main issue. The origin minimizing Spillage starts at the stage. Correct conveyor layout particularly for the loading and move zones is the secret. Occasionally the Procurement of the cheapest is going to be to the detriment of their long-term investment. Sacrifices to crucial design components into the conveyor-structure and conveyor-components like sealing skirts, belt cleaners, transitional chutes, idlers or influence beds could be compromised or overlooked.

Also the Electric control system, conveyor speed and startup sequence are important aspects to think about during procurement. Belt skirting Structures should contain a commercially available system that allows for easy interchangeability and modification of the sealing membrane. The skirting seal must just gently skim the surface of the conveyor-belt while excess contact will wear the seal cartilage and buckle coating. Belt monitoring issues and extra drag on the power-train might also be a byproduct. The usage of homemade Skirts, unless intended properly can be hard to adjust and supply irregular belt contact

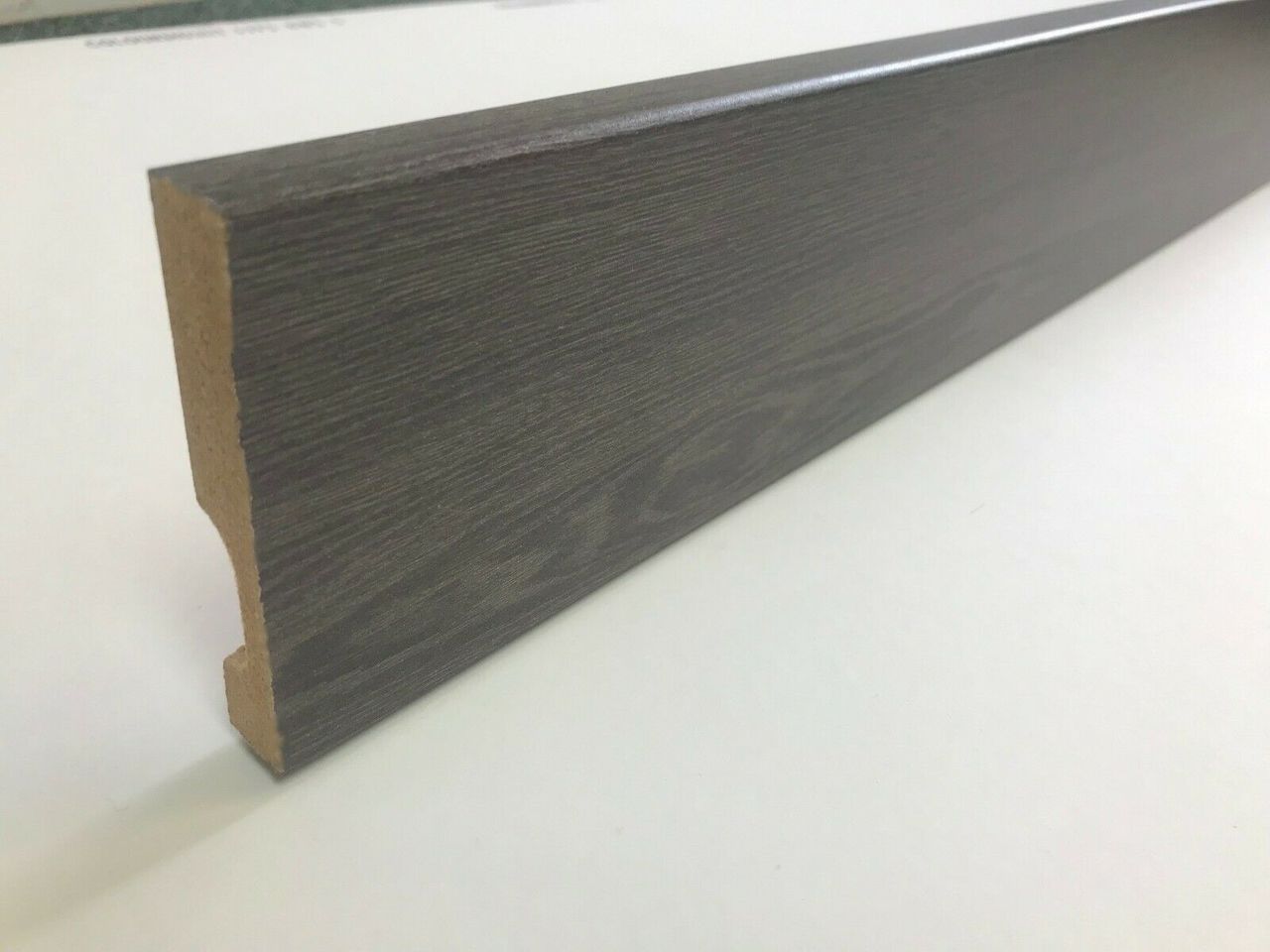

An easily adjustable Skirt will make it possible for the trades-person to fine tune the sealing system and also be more inclined undertaken as a normal maintenance process. Transition and load Zones should be equipped with adequate roller assistance or impact beds under the belt to stop belt-sag. Belt deflection present entrapment points and would exacerbate spillage involving the skirts. Proper alignment of Transfer zones involving adjoined conveyors or procedure plant is suggested. It is essential for the substance to be packed in a controlled flow professionally on the conveyor belt and evenly between the skirting boards and get best skirting board. Misalignment enables refuse to trickle over skirting seals, present monitoring issues and harm to the pulleys and elements.

Load zones should think about the fall distance in the pre-feeder conveyor on the belt. To shield elements and decrease airborne dust that this spacing ought to be made to a minimum for fines or Dusty solution, like gypsum or chemical compounds, it can be hard to catch 100 percent of airborne particles. 1 option to decrease this threat is to completely encapsulate the belt and also apply an integral extraction system, in especially for indoor centers in which occupational hazards are an opportunity. Transfer zones and Belt-cleaner tailings may be debatable regions for substance spills. If the spillage is included into an isolated place then an additional scavenger conveyor could be contemplated. A Variety of scavenger, Tailings conveyors, drag-chain-conveyors or vibratory conveyors mounted under the substance origin may show the remedy to accumulate and return the spillage into the transport chute.